Permanent magnet variable speed screw air compressor, with synchronous motor, has no slip, no electrical excitation and low heat loss.

Product Advantages

Permanent magnet motor

The motor IP54 and the main engine share the same shaft, without coupling, central bracket, belt, gear, etc. The transmission efficiency is 100%, whose efficiency is 5-12% higher than that of the same capacity asynchronous motor. The motor is bearingless and oil sealed, eliminating routine maintenance and repairation. The volume is half smaller than the main component of ordinary three phase motor, and the weight is one-third lighter than that of the common motor host component.

Frequency inverter

Frequency conversion operation, start smoothly and stably with low noise. The large reduction of the starting current reduces the maximum power load, so as to save a lot of electricity. The demand of compressed air is varied every time depend on loading condition and the fluctuation rate is 40 - 80%. With application of Inverter Control system, the compressed air can be produced accurately according to the demand. And eventually, it can make much energy saving compared to normal compressor.

Intelligent control

Through higher intelligent control, the size of air production can be adjusted automatically, therefore, no matter how the air volume fluctuates, the pressure is always maintained which means the operation is really under constant pressure. The motor responds quickly, starts quickly and loads quickly.When the air volume is suddenly changed, it can respond quickly and the reaction time is within 50ms. It completely avoids the damage of uers' equipment and product defects caused by the pressure tuation, moreover, it reduces the energy loss caused by the pressure fluctuation.

Energy Saving Airend

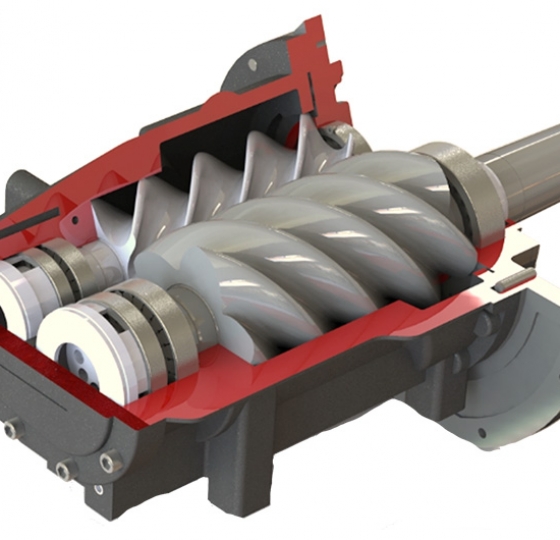

Energy Saving Airend (using 6 SKF bearings)

With new and exclusive design of Typhoon screw rotor which has been passed through the accurate machining procedure and test, it improves efficiency of airend and optimizes the airflow. We use a set of opposite biconical roller bearings at the end of exhaust end enable to support thrust load effectively and extend the running time.

Energy Saving Intake Valve

Intake valve have function of proportional adjusting the air inflow, according to user's air demand, intake volume can be adjusted from 0-100%.

With non-return function,

With air-bleeding function,

With no-load delay function

High capability cooling system

Using axial fan, large propeller, lower speed and lower noise. With high air pressure, high air volume and stable operation.

Large heat exchanger, using high strength aluminum alloy material, ensure good cooling effect even under 45 degree environment.

Product Parameter

| TPM SERIES TECHNICAL SPECIFICATION |

| Model |

Power |

Pressure |

Capacity |

Dimensions |

Weight |

Outlet Pipe |

Noise Level |

| KW |

HP |

bar |

M3/min |

(LxWxH) mm |

Kg |

Diameter |

dB |

| TPM7.5A |

5.5 |

7.5 |

7 |

0.90 |

840x670x925 |

200 |

G3/4 |

65 |

| 8 |

0.80 |

| 10 |

0.70 |

| 13 |

0.60 |

| TPM10A |

7.5 |

10 |

7 |

1.05 |

840x670x925 |

200 |

G3/4 |

65 |

| 8 |

1.10 |

| 10 |

1.00 |

| 13 |

0.80 |

| TPM15A |

11 |

15 |

7 |

1.68 |

1000x820x1145 |

300 |

G3/4 |

65 |

| 8 |

1.60 |

| 10 |

1.45 |

| 13 |

1.30 |

| TPM20A |

15 |

20 |

7 |

2.50 |

1000x820x1145 |

300 |

G3/4 |

65 |

| 8 |

2.30 |

| 10 |

2.00 |

| 13 |

1.74 |

| 15 |

1.50 |

| TPM30A |

22 |

30 |

7 |

3.52 |

1100x880x1190 |

390 |

Gl 1/4 |

75 |

| 8 |

3.36 |

| 10 |

3.06 |

| 13 |

2.80 |

| 15 |

2.20 |

| TPM40A |

30 |

40 |

7 |

5.20 |

1200x950x1358 |

530 |

Gl 1/4 |

75 |

| 8 |

4.72 |

| 10 |

4.30 |

| 13 |

3.90 |

| TPM50A |

37 |

50 |

7 |

6.51 |

1300x1000x1366 |

590 |

Gl 1/2 |

75 |

| 8 |

6.19 |

| 10 |

5.62 |

| 13 |

5.10 |

| TPM60A |

45 |

60 |

7 |

7.71 |

1300x1000x1366 |

590 |

Gl 1/2 |

80 |

| 8 |

7.35 |

| 10 |

6.67 |

| 13 |

5.80 |

| TPM75A |

55 |

75 |

7 |

10.14 |

1600x1300x1600 |

1210 |

G2 |

80 |

| 8 |

9.66 |

| 10 |

8.77 |

| 13 |

7.95 |

| TPM100A |

75 |

100 |

7 |

13.50 |

1600x1300x1600 |

1210 |

G2 |

80 |

| 8 |

12.51 |

| 10 |

11.21 |

| 13 |

9.78 |

| TPM120A |

90 |

120 |

7 |

14.91 |

1600x1300x1600 |

1220 |

G2 |

85 |

| 8 |

14.17 |

| 10 |

12.88 |

| 13 |

11.50 |

| TPM150A |

110 |

150 |

7 |

20.96 |

2090x1550x2000 |

2300 |

DN65 |

85 |

| 8 |

20.06 |

| 10 |

17.02 |

| 13 |

15.30 |

| TPM175A |

132 |

>175 |

7 |

23.37 |

2090x1550x2000 |

2300 |

DN65 |

85 |

| 8 |

22.50 |

| 10 |

21.03 |

| 13 |

18.00 |

- The exhaust volume is measured under the rated exhaust pressure, according to the national standard GB3853 test (equivalent to ISO1217 appendix C).

- Recommend frquency 30%-100%.

- The above data is based on the standard grid- 380V/ 50HZ.

- Please make further inquiry for the non-standard specification type and machines which are used under high/low temperature, high humidity, dusty working environment.