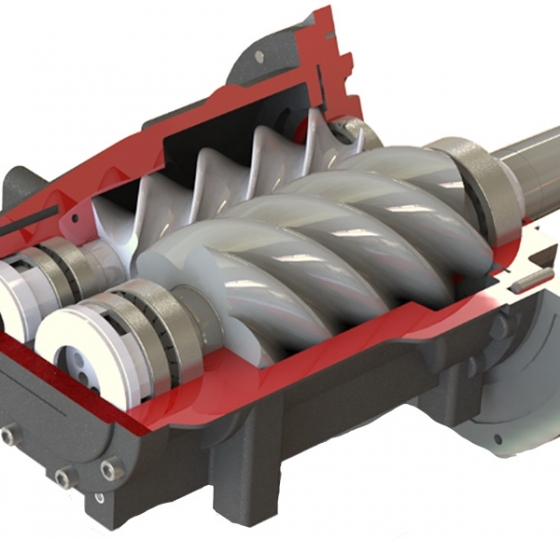

Advanced V-profile air end and high precision processing, provide highest efficiency with its high volume flow rate.

Product Advantages

Oil & Air separator

Three-stage separation of oil and gas is achieved: Centrifugal separation, gravity separation, separation by fine core. With high-efficiency oil-air separator to ensure that the compressed air oil content is less than 3ppm. High-precision large-capacity oil separator using time can be up to 4000 hours

Oil filter

Adopt the spin-on oil filter, easy to install and replace. Ensure good oil supply status of air end, extend the service life of air end by better protection. Filter fineness: 10-12μm.

Initial pressure differential: ≤0.03Mpa

High precision air filter

The air filter element is using high precision imported filter material. Extend the life time of machine. Main function of air filter is filter the dust from air, avoid the screw rotor wear off, prevent clog of oil filter and oil-air separator.

The filter paper hole is around 10micron

Intelligent control system

Adopt micro-computer control system, which have self-checking and self-protection function. A good human-machine interaction design, can display the actual operation status of machine, enabling self-checking of the system before start up, and it can monitor all safety-related parameters during operation. If the unit has fails, the computer control system will respond accordingly to different situations.

Hard tube connection

Machine adopt hard tube connection, which improved the reliability and service life of pipeline system. Corrosion-resistant treatment, long-term use without hidden dangers.Cone seal + O-ring seal double insurance, no leakage. Neat and beautiful, visual experience is better.

High capability cooling system

Using axial fan, large propeller, lower speed and lower noise. With high air pressure, high air volume and stable operation.

Large heat exchanger, using high strength aluminum alloy material, ensure good cooling effect even under 45 degree environment.

Product Parameter

| TFS SERIES TECHNICAL SPECIFICATION |

| Model |

Power |

Pressure |

Capacity |

Dimensions |

Weight |

Outlet Pipe |

Noise Level |

| KW |

HP |

bar |

M3/min |

(LxWxH) mm |

Kg |

Diameter |

Db |

| TFS7.5A |

5.5 |

7.5 |

7 |

0.90 |

840x670x925 |

210 |

G3/4 |

65 |

| 8 |

0.80 |

| 10 |

0.70 |

| TFS10A |

7.5 |

10 |

7 |

1.20 |

840x670x925 |

210 |

G3/4 |

65 |

| 8 |

1.10 |

| 10 |

1.00 |

| TFS15A |

11 |

15 |

7 |

2.00 |

1000x820x1145 |

330 |

G3/4 |

65 |

| 8 |

1.60 |

| 10 |

1.44 |

| TFS20A |

15 |

20 |

7 |

2.50 |

1000x820x1145 |

330 |

G3/4 |

65 |

| 8 |

2.30 |

| 10 |

2.00 |

| TFS25A |

18.5 |

25 |

7 |

3.10 |

1100x880x1190 |

440 |

Gl 1/4 |

75 |

| 8 |

2.90 |

| 10 |

2.60 |

| TFS30A |

22 |

30 |

7 |

3.52 |

1100x880x1190 |

440 |

Gl 1/4 |

75 |

| 8 |

3.36 |

| 10 |

3.06 |

| TFS40A |

30 |

40 |

7 |

5.20 |

1200x950x1358 |

620 |

Gl 1/4 |

75 |

| 8 |

5.00 |

| 10 |

4.50 |

| TFS50A |

37 |

50 |

7 |

6.51 |

1300x1000x1366 |

650 |

Gl 1/2 |

75 |

| 8 |

6.20 |

| 10 |

5.70 |

| TFS60A |

45 |

60 |

7 |

8.80 |

1300x1000x1366 |

670 |

Gl 1/2 |

80 |

| 8 |

7.50 |

| 10 |

6.90 |

| TFS75A |

55 |

75 |

7 |

10.30 |

1600x1300x1600 |

1220 |

G2 |

80 |

| 8 |

9.66 |

| 10 |

8.77 |

| TFS100A |

75 |

100 |

7 |

13.5 |

1600x1300x1600 |

1220 |

G2 |

80 |

| 8 |

12.50 |

| 10 |

11.20 |

| TFS150A |

110 |

150 |

7 |

21.0 |

2090x1550x2000 |

2300 |

G2 |

85 |

| 8 |

20.00 |

| 10 |

17.0 |

| TFS175A |

132 |

175 |

7 |

23.50 |

2090x1550x2000 |

2300 |

DN65 |

85 |

| 8 |

22.50 |

| 10 |

21.00 |

- The exhaust volume is measured under the rated exhaust pressure, according to the national standard GB3853 test (equivalent to ISO1217 appendix C).

- Recommend frquency 30%-100%.

- The above data is based on the standard grid- 380V/ 50HZ.

- Please make further inquiry for the non-standard specification type and machines which are used under high/low temperature, high humidity, dusty working environment.